FIL (rod)

Filter

Shopping Options

- Guide Ring (Rod) POM Type: FIL

Dimensions: 120 x 126 x 5 x 16Part number: 6543269In StockMore Details - Guide Ring (Rod) POM Type: FIL

Dimensions: 141 x 147 x 5 x 16Part number: 6543272In StockMore Details - Guide Ring (Rod) POM Type: FIL

Dimensions: 183 x 189 x 5 x 16Part number: 6543274In StockMore Details - Guide Ring (Rod) POM Type: FIL

Dimensions: 207 x 213 x 5 x 16Part number: 6543275In StockMore Details - Guide Ring (Rod) POM Type: FIL

Dimensions: 60 x 66 x 5 x 16Part number: 6543259In StockMore Details - Guide Ring (Rod) POM Type: FIL

Dimensions: 78 x 84 x 5 x 16Part number: 6543262In StockMore Details

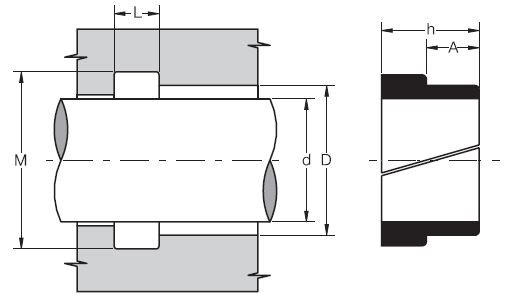

Guide ring type FIL (rod)

The Aston Seals FIL type guide rings have been developed to substitute traditional bronze guides in hydraulic cylinders. They guide the rod and prevent metallic contact with the cylinder head when radial forces act perpendicular to the direction of movement. Chamfered edges prevent splintering of the material during assembly and make the installation into the groove easier. The compound used for these guides is a medium viscosity glass fibre reinforced acetal resin characterized by high strength, rigidity, hardness, impact resistance, resilience and excellent stability to high and low temperature

This results in:

- Extended service life

- Excellent wear-resistance

- Simple design of groove and assembly

- Low friction

- Good resistance to loads

- Good mechanical stability at high temperature

- Easy installation without expensive auxiliaries

Other information:

- Material: Acetal resin with glass fibre

- Speed: ≤ 1 m/s

- Temperature: –40°C tot +110°C

- Surface roughness: dynamisch (Ra ≤ 0.3 µm / Rt ≤ 2.5 µm) & statisch (Ra ≤ 2 µm / Rt ≤ 10 µm)

Sizes

| part | d (f7) | D (+0,05) | M (+0,2) | L (+0,1) | h | A |

| 6543242 | 45 | 51 | 56 | 5 | 13 | 8 |

| 6543258 | 60 | 66 | 71 | 5 | 13 | 8 |

| 6543259 | 60 | 66 | 71 | 5 | 16 | 11 |

| 6543260 | 65 | 70 | 73 | 5 | 16 | 11 |

| 6543261 | 72 | 77 | 82,4 | 5 | 16 | 11 |

| 6543301 | 75 | 81 | 86 | 5 | 13 | 8 |

| 6543262 | 78 | 84 | 89 | 5 | 16 | 11 |

| 6543263 | 85 | 90 | 93 | 5 | 16 | 11 |

| 6543264 | 91 | 96 | 101,4 | 5 | 16 | 11 |

| 6543265 | 95 | 101 | 106 | 5 | 13 | 8 |

| 6543266 | 99 | 105 | 110 | 5 | 16 | 11 |

| 6543267 | 110 | 115 | 120,4 | 5 | 16 | 11 |

| 6543268 | 115 | 121 | 126 | 5 | 13 | 8 |

| 6543269 | 120 | 126 | 132 | 5 | 16 | 11 |

| 6543270 | 129 | 136 | 139,4 | 5 | 16 | 11 |

| 6543271 | 132 | 138 | 143 | 5 | 13 | 8 |

| 6543272 | 141 | 147 | 152 | 5 | 16 | 11 |

| 6543273 | 162 | 168 | 173 | 5 | 16 | 11 |

| 6543274 | 183 | 189 | 194 | 5 | 16 | 11 |

| 6543275 | 207 | 213 | 218 | 5 | 16 | 11 |