RS-11

-

- Rod Seal PTFE Bronze O‑ring FKM 80 Type: RS-11

Dimensions: 10 x 14.9 x 2.2Part number: 6542087Delivery 1-5 daysMore Details

- Rod seal HPU 57D O‑ring NBR 70 Type: RS-11

Dimensions: 10 x 14.9 x 2.2Part number: 6542088Delivery 1-5 daysMore Details

- Rod Seal PU 58D O‑ring NBR 70 Type: RS-11

Dimensions: 10 x 14.9 x 2.2Part number: 6542089Delivery 1-5 daysMore Details

- Rod Seal PU 72D O‑ring NBR 70 Type: RS-11

Dimensions: 10 x 14.9 x 2.2Part number: 6534471Delivery 1-5 daysMore Details

- Rod seal PTFE Carbon O‑ring NBR 70 Type: RS-11

Dimensions: 10 x 14.9 x 2.2Part number: 6561990Delivery 1-5 daysMore Details

RS-11

Description

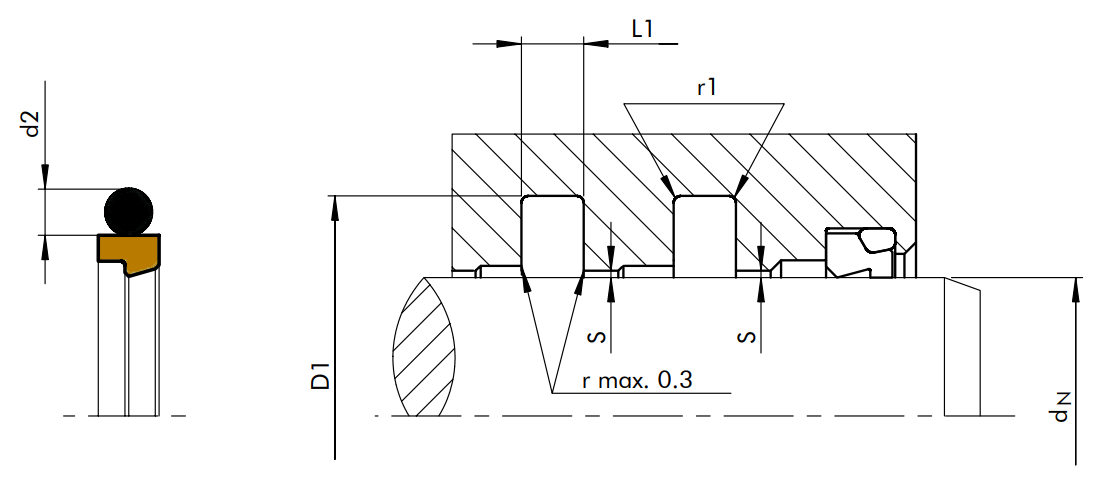

The RS-11 is a single acting seal and consists of a PTFE sealing element, which is pre-stressed by an O-ring. The RS-11 has an exceptionally good sealing function under strong loads and a good static tightness.

PTFE seal with O-ring energized element, sealing on the inside, one side pressure loaded.

Sealing material: PTFE, energized by an O-ring, material: NBR 70 shore.

| Description | Materials | Temperature (°C) | Temperature (°C) | Speed | Pressure |

| single acting | PTFE bronze | to -30 | to 100 | to 15 m/s | to max. 40 MPA |

| + O-ring NBR | |||||

| single acting | PTFE bronze | to -15 | to 200 | to 15 m/s | to max. 40 MPA |

| + O-ring FKM | |||||

| single acting | PU 72D | to -30 | to 100 | to 2 m/2 | to max. 460 MPA |

| + O-ring NBR |

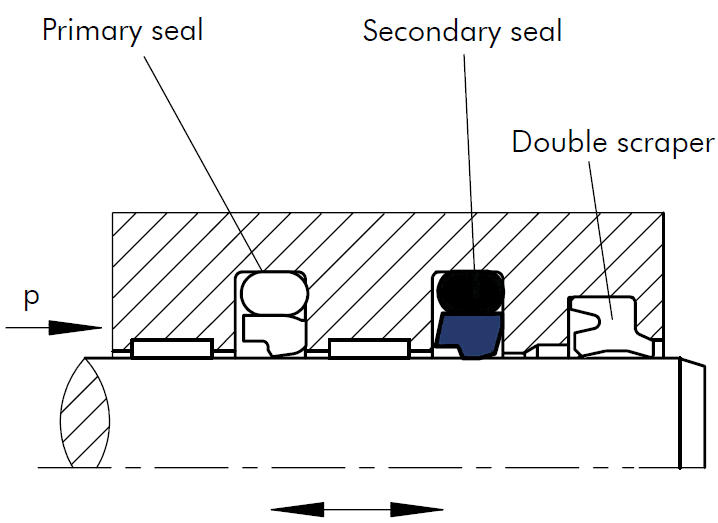

Secondary seal

When there is a tandem installation (2 seals in a row), the second seal (secondary) is made of a PU material. The main seal (primary) is always made of a PTFE compound.

The Tandem installations are used in applications where it is uncertain that one seal will seal properly.

Hydraulic oils according to DIN 51524 parts 1 - 3, lubricating oils, mineral-based greases, flame-retardant hydraulic fluids HFA, HFB, HFC according to VDMA 24317, water and water-oil emulsions.

Applications

- for sealing hydraulic rotation

- sealing of reciprocating or rotating rods / shafts

Installation

For smaller diameters, installation requires an open installation space. For larger diameters, the seals can be mounted in a closed installation space.

Afterwards calibration is necessary.

We can also produce this rod seal on request in the materials below. This is our type DS129.

| Material | Color | Dimensions |

| Virgin PTFE | White | 0 to 500 mm |

| PTFE with 40% Brons | Brown | 0 to 500 mm |

| PTFE with 25% Carbon | Gray | 0 to 500 mm |

| PTFE with 15% Glass and 5% MoS2 | Gray | 0 to 210 mm |

| PTFE with 25% Glass | White | 0 to 150 mm |

| PTFE with 15% Grafiet | Black | 0 to 150 mm |

| PTFE with 1% Turquoise | Turquoise | 0 to 150 mm |

| UHMW-PE | Naturel | 0 to 130 mm |

Material reference table

| Colour | Content | Seal Supply | Trelleborg | Simrit | Merkel | ERIKS | Dichtomatik |

| White | Pure PTFE, (Virgin) | K11 | T01 | 528 | MT 01 | ER-01 | PTFE 00 98 03 |

| Dark grey | PTFE Bronze MoS2 Modified | K12 | T46 | 552/40 | MT 28 | ER-39 | PTFE 00 98 16 |

| Light green | PTFE Bronze Modified | K13 | T47 | PTFE 00 98 07 | |||

| Brown | PTFE Bronze MoS2 Modified | K16 | T08 / T53 | 552/60 | MT 25 | PTFE 00 98 20 | |

| Light green | PTFE Bronze Modified | K18 | T08 / T53 | PTFE 00 98 22 | |||

| Black | PTFE Graphite | K21 | T12 | ER-81 | PTFE 00 98 24 | ||

| Black | PTFE Carbon Graphite | K22 | T10 / T51 | 561/25 | MT 12 | ER-59 | PTFE 00 98 09 |

| Black | PTFE Carbon Graphite | K25 | T24 | ER-31 | PTFE 00 98 08 | ||

| Black/grey | PTFE Carbon fiber | K28 | T40 | PTFE 00 98 10 | |||

| Blue | PTFE Filler | K30 | T56 | ER-99 | PTFE 00 98 25 | ||

| Grey/Blue | PTFE MoS2 Modified | K31 | T99 | PTFE 00 98 26 | |||

| Turquoise | PTFE Filler | K32 | T05 | PTFE 00 98 06 | |||

| Cream | PTFE Ekonol | K40 | T78 | PTFE 00 98 04 | |||

| Light blue | PTFE Glass fiber Modified | K460 | T101 | PTFE 00 98 29 | |||

| Turquoise | PTFE Glassfiber Filler | K61 | T06 | PTFE 00 98 12 | |||

| Grey | PTFE Glass fiber MoS2 Modified | K66 | T42 | 537/15 | MT 72 | ER-48 | PTFE 00 98 13 |

| White | PTFE Glass fiber | K70 | T03 | PTFE 00 98 11 | |||

| Yellow | Polyurethane shore 58D | K86 | Z54 (1) | TPU00 98 04 | |||

| Yellow | Polyurethane shore 72D | K87 | Z53 (2) | TPU 00 98 01 | |||

| White | UHMW PE | K90 | Z80 | PE 00 98 01 | |||

| Grey | PTFE Carbon fiber Graphite Filler | K114 | T29 | PTFE 00 98 38 | |||

| Yellow | Polyurethane shore 95A | K116 | Z20 | TPU 00 98 02 | |||

| Black/grey | PTFE PPS Carbon/MoS2 | K123 | T77 | PTFE 00 98 42 | |||

| (1) before Z52 | |||||||

| (2) before Z51 |

Deze stangafdichting kunnen wij op aanvraag ook zelf produceren in onderstaande materialen. Dit is ons type DS129.

| Materiaalomschrijving | Kleur | Afmetingen |

| Polyurethane 72° Shore D (Z51®) | Naturel | 5 tot 300 mm |

| Polyurethane 58° Shore D (Z52®) | Naturel | 5 tot 300 mm |

| Polyurethane 57° Shore D | Blauw | 5 tot 500 mm |

| Virgin PTFE | Wit | 5 tot 500 mm |

| PTFE met 40% Brons | Bruin | 5 tot 500 mm |

| PTFE met 25% Carbon | Grijs | 5 tot 500 mm |

| PTFE met 15% Glas en 5% MoS2 | Grijs | 5 tot 210 mm |

| PTFE met 25% Glas | Wit | 5 tot 150 mm |

| PTFE met 15% Grafiet | Zwart | 5 tot 150 mm |

| PTFE met 1% Turquoise | Turquoise | 5 tot 150 mm |

| UHMW-PE | Naturel | 5 tot 130 mm |